Nitrogen Injection & Oil Evacuation System

(Transformer Explosion Prevention & Fire Extinguishing System)

Why NIOES (NIFPS)

Transformer is among the most expensive equipment located in power plants and substation etc. They generally contain a large quantity of combustible substance, which can spread fire to nearby installations also and caused a power failure and so huge economic losses. Special attention should therefore be paid for their protection.

The traditional System like “High Velocity Water Spray System / Co2 Gas Flooding System” provides external protection of the transformers and they come into operation once the Fire got initiated around the transformer for the reason whatsoever or in case transformer already got exploded. Whereas “Nitrogen Injection Explosion prevention & Fire Protection System” is an internal protection of the transformer as it prevents the Transformer from its explosion which generally occurs due to over heating / overloading / winding Short-circuiting or for any earth fault etc.,

Please note that this system does not protect the transformer from its external Fire, since Nitrogen is injected inside the body of the transformer, Therefore “Nitrogen Injection Explosion prevention System” is not an alternative for HVWS / Co2 Flooding System but its Installation is recommended in addition to HVWS / Co2 Flooding System.

Fire Incidents of Transformer

“Tri-Parulex Nitrogen Injection Explosion prevention & Fire Protection System” is more advanced Transformer prevention for oil immersed transformers in compare to water spray (HVWS) System and Co2 Flooding System.

System Installation

Major Components

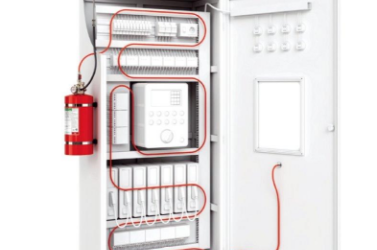

Fire Extinguishing Cabinet

Control Panel (PLC / SCADA (Optional)

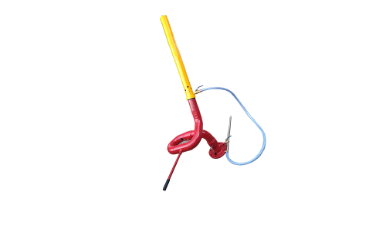

TCIV

Control Panel

Fire Detector

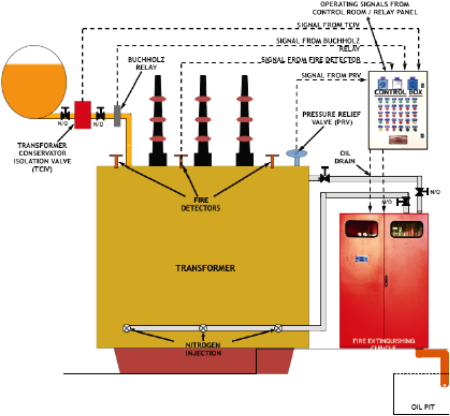

General Arrangement of the System

The Tank Explodes

The Tank Is Safe

Characteristics of Tri-Parulex NIOES

State-of-art concept : Rapidly drain oil to prevent explosion and inject nitrogen to prevent and extinct fire.

Excellent performance : Utilizing fast valves to drain oil within seconds with the most advanced technique.

Fast response : Once a fault signal is detected from the Transformer. The oil is drained within second after detection in order to release pressure and to avoid explosion. The nitrogen gas is injected after 1 to 20 second in order to mix and cool down the oil, to reduce the concentration of flammable gases, to isolate oxygen gas, and to extinct fire.

Reliability : Utilizing the principle of logic signal to prevent any improper or unnecessary activity to the system and to provide a more flexible system.

High efficiency : Able to inject nitrogen gas continuously for more than 30 minutes to completely cool down the transformer oil as well as prevent and extinguish fire.

Reduce pollution : No Environmental pollution due to the characteristic of nitrogen gas. Extinct fire without water is an advantage to the lack of water area.

Feasibility : Easy to install and maintain for both new or existing transformers with reasonable investment in a minor price compare to other traditional transformer fire extinction systems, such as water spraying systems and CO2 spraying systems.

Functions : Explosion Prevention and Fire Extinguishing system can extinguish the fire immediately with the Nitrogen Gas injected into the Transformer Tank.

The Nitrogen can be injected continuously for 30 Minutes to stir and cool down the transformer oil, which also isolated the air from the tank.

Scope of Application

Generator Power is unceasingly increasing with the development of technology, there are many transformer explosion happened due to ineffective of current breaker between the Generator and Power Transformer.

Tri-Parulex Nitrogen Injection Systems is suitable for new or remodeled Power transformer which are located in the high power plant, substations, indoor substations, underground substations, city substations and cold water deficient areas.

How Transformer Explodes & Catch Fire

An Arc is generated due to any internal fault in the Transformer and a high energy flows through transformer which lead to decomposition of insulation/oil at high temperature. Top oil surface attains temperature higher than ignition point. Huge thermal energy is generated thereby emitting combustible gases. Pressure built-up resulting in tank rupture normally at top cover. Hot oil when comes in contact with the oxygen catches fire.

Benefits of NIOES

- On activation, the system extinguish the Fire within seconds.

- It prevent the Transformer from explosion.

- Nitrogen Gas is inert and does not react with transformer oil.

- It is completely Non-Toxic & Non-hazardous.

- It provides best cooling effect to the oil inside the Transformer.

- Forms insulating layer of N2 Blanket on top surface of the oil.

- Less Cost of Installation & Maintenance.

- Environment Friendly.

- Best System for the Areas of water Scarcity.

- CNF Spray System for External Fire Protection ( Optional ).

Our System's USP

Auto Dialer Facility - a pre-recorded message will be sent to already registered phone numbers in the system in case of any system activation. (Max 3 numbers)

A mechanical interlocking has been provided to ensure that nitrogen injection will not take place into the transformer until the oil drain valve is open.

All the products share a long standing reputation for technical excellence, providing the most cost-effective solutions for your need.

Nitrogen Injection &

Evacuation system for Transformers

High / Low Pressure

Water Mist Fire Suppression System

Foam Flooding

/ Pouring / Spray system

Gas Based

Fire Suppression System

Quick Detection

& Suppression Tubing System

Medium & high

velocity water spray system

CAF

Portable Extinguisher

Fire

Detection & Alarm System

Hydrant, sprinkler's

accessories and Fire Extinguisher

We have wide variety of product accessories including our major product components.

High/ Low

pressure Water Mist Nozzles

High

Pressure Water Mist Gun

Fog /

Misting Nozzle

High / Medium

Velocity Water Spray Nozzle

Mobile

Foam Unit

Mobile

CAF Unit

Foam

Maker & Foam Chambers

Orifice

Plate

Foam

Inline Inductor

Foam

Monitor

Fire Hose

& Hydrant Accessories

Clean

Agent Fire Extinguisher

Nitrogen Injection Transformer

Fire Protection Accessories

Quick Detection & Suppression

Tubing System Accessories